Home> Company News> Choose the correct lubricating oil for opencast mining equipment

- Address4 Pemimpin Drive #03-09, Lip Hing Industrial Building

- Factory AddressSingapore 576147

- WorktimeSeg - Sex (9.00 - 18.00) Sáb (9: 00-12: 00)

- Phone(Working Time)(65) 8257 8518

- Phone(Nonworking Time)(65) 8257 8518

- Fax(65) 6258 7399

At present, some large-scale open-pit coal mining equipment generally has the characteristics of large production capacity, high automatic function and high investment in single equipment. Therefore, based on these characteristics, if the equipment is damaged, it will be produced for mining. The development has caused great losses. In the process of managing open-pit mining equipment, the management of lubrication is the main aspect of management.

Lubrication management has a direct relationship with the service life, production revenue and equipment maintenance cost. According to the survey statistics, in the failure of open-pit mining equipment, 80% of the mechanical failures occurred after the equipment parts failed due to wear and tear, and the factors affecting the wear and tear were the poor lubricity of the equipment. It can be seen that from the perspectives of quality inspection, correct use, management system, correct selection and three analytical equipments of lubricating oil, the lubrication management of open-pit mining equipment is introduced and analyzed, and the lubrication management of equipment is strengthened. The life of the equipment, the improvement of equipment efficiency, the reduction of equipment maintenance costs and the reduction of equipment failures play a very important role.

Lubricating oils used in open pit mining equipment mainly include lubricating grease and lubricating oil.

Lubricating grease

In the choice of lubricating grease, it is necessary to determine the type of lubricating grease in terms of temperature, shock and vibration, temperature and pressure in the mechanical lubrication position. In addition, the humidity and temperature in the environment, whether there is contact with corrosive substances, etc. These conditions should also be taken into account.

There are many types of lubricating oils, and different lubricating oils have their own lubricating properties, such as oxidation stability, viscosity, anti-foaming properties, shear stability, abrasion resistance, rust and corrosion resistance, etc. The mechanical friction conditions are observed to select the lubricating oil, for example, for its speed, pressure, humidity, and blending properties of the lubricating oil and the seal. In order to ensure the lubricating oil has good lubricating performance, the lubricant manufacturer will specify the lubricating oil in its equipment. Therefore, in the selection of lubricating oil, the requirements of the manufacturer must be met. Especially those imported products that are more expensive, pay more attention to the regulations and requirements of oil products. In the choice of domestic oil to replace imported oil, it is necessary to select each kind of lubricating oil with similar performance and index similar to imported oil, and also carry out strict testing on its index and performance, which has reached the required equipment lubricity. Satisfaction.

In the selection of lubricating grease and lubricating oil, on the one hand, it is necessary to select lubricating oils that have better lubricating quality and at the same time enable the equipment to achieve lubrication. On the other hand, it is necessary to make the correct choice for the manufacturer, because in some In the case, although the lubricating oil belongs to the same model, the quality of the produced lubricating oil is different due to the difference in the manufacturer. Usually brand-name and relatively large lubricant manufacturers will produce better quality lubricants, and the quality of the imported lubricants is also good. The quality of lubricants sold by small manufacturers is relatively poor. Of course, it cannot be said that the quality of lubricants produced by small manufacturers is poor, and there are also small manufacturers that produce high-quality lubricants. All in all, in the choice of lubricants, quality should be ranked first, in addition to the importance of the producer's reputation is also very important.

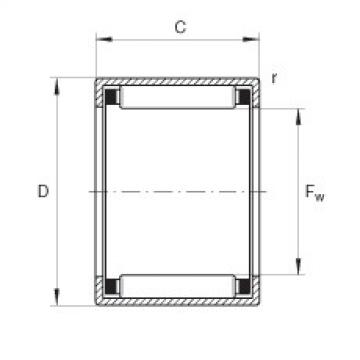

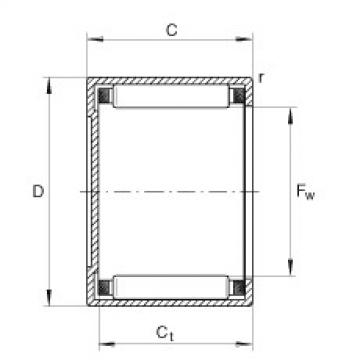

FAG Nadelhülsen - HK2030-ZW

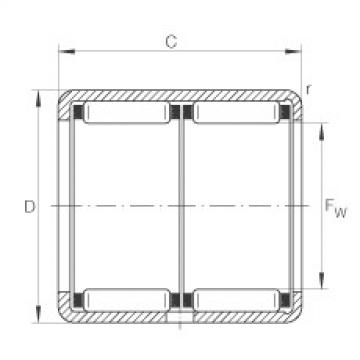

FAG Nadelhülsen - HK2030-ZW FAG Nadellager - RNA6902-XL

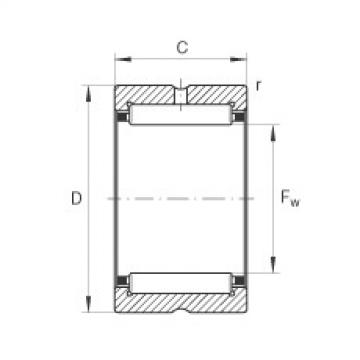

FAG Nadellager - RNA6902-XL FAG Nadelhülsen - HK2016

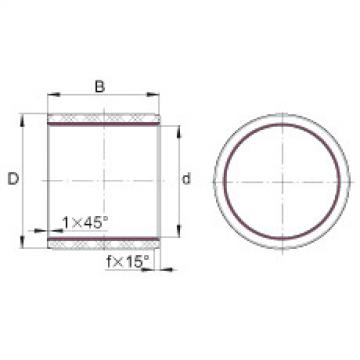

FAG Nadelhülsen - HK2016 FAG Gleitbuchsen - ZWB202415

FAG Gleitbuchsen - ZWB202415 FAG Nadelbüchsen - BK2016

FAG Nadelbüchsen - BK2016