Home> Company News> How to use Lubricating oil for tractor?

- Address4 Pemimpin Drive #03-09, Lip Hing Industrial Building

- Factory AddressSingapore 576147

- WorktimeSeg - Sex (9.00 - 18.00) Sáb (9: 00-12: 00)

- Phone(Working Time)(65) 8257 8518

- Phone(Nonworking Time)(65) 8257 8518

- Fax(65) 6258 7399

Tractor is widely used in agricultural production for deep loosening, land preparation, sowing, harvesting and transportation operations. As tractor power continues to increase, the performance of tractor lubricants is becoming more and more important. The lubricating oil for tractors mainly includes diesel engine oil, gear oil, hydraulic oil, transmission oil, etc. If the oil used for oil selection is improper, the tractor will fail frequently and the service life will be reduced.

1 Selection of diesel engine oil

The oil acts as a lubricant, cooling, cleaning and sealing in the engine. The oil forms an oil film between the engine fittings, reducing friction between the moving pairs, reducing wear and increasing the service life of the fittings. The circulating flow of the oil can take away the heat of the surface of the part and have the function of cooling the engine. It can also take away the wear products in the working part and the carbon particles generated in the combustion to reduce the wear of the machine.

GB 11122-2006 diesel engine oil standard, the oil quality grade is divided into six quality grades such as CC, CD, CE, CF-4, CH-4 and CI-4, C' indicates diesel oil, the quality of the English letters is higher. The higher the level. When choosing to use diesel engine oil, generally choose the one with lower viscosity and use multi-grade oil as much as possible. CC grade diesel engine oil is a common engine oil with certain cleaning dispersibility, oxidation resistance and corrosion resistance. It is suitable for naturally aspirated diesel engines, small and medium-sized tractors with a speed of ≤2000 r/min and a power of ≤18.38 kW per cylinder. Transport vehicle. CD and CE diesel engine oils are medium-range oils with good cleaning and dispersibility, oxidation resistance, corrosion resistance and abrasion resistance. They are suitable for domestic high-power diesel vehicles, large tractors and combine harvesters. CF diesel engine oil is suitable for all types of internal combustion engines, especially indirect injection diesel engines. CF-4 diesel engine oil is suitable for road trucks and passenger car diesel engines. CH-4 diesel engine oil is suitable for heavy duty road trucks and diesel engines for high horsepower engineering machinery.

Due to the continuous improvement of the quality of internal combustion engine lubricating oil, it is now impossible to replace the oil only by the mileage or oil change interval, but should be replaced according to the quality and usage of the used oil. When the vehicle is in good condition, the oil change time can be extended appropriately. If the vehicle condition is poor, the oil change time should be shortened. New diesel engines should use less viscous lubricants; while diesel engines with longer wear and greater wear (gap increases) can be used with larger viscosity lubricants.

The old oil should be drained when changing the oil. After a period of use of the oil, the oil will contain moisture, fuel, metal abrasives and combustion products, so that the additives (antioxidants, detergent dispersants, etc.) in the oil will be invalid, and the oil will lose its lubricating properties. These moisture, impurities, and acidic substances in the oil can also contaminate the newly added engine oil and affect the performance of the new oil. When changing the oil, you should replace the filter element of the oil filter to prevent the filter element from being lost due to dirt.

Gear oil is mainly used on the tractor chassis to lubricate the transmission gears. The gear oil produced in the past is made by adding engine oil to the residue. Now it is directly distilled from crude oil, and its crush resistance and corrosion resistance have been greatly improved.

The gear oil is divided into three grades according to normal load, medium load and heavy load. There are six viscosity grades of 70W, 80W, 85W, 90W, 100W and 250W, and 80W/90 and 85W/90 are multi-grade gear oils for vehicles.

The main basis for selecting vehicle gear oil is mechanical power and rear axle gear load. The high-powered tractor has high speed and high power, and the gear contact stress is quite high (up to 1.96×103~294×103 MPa). Therefore, the quality index of the vehicle gear oil is correspondingly high. In general, the gear oil (70W, 80W) of ordinary gears can reach 6×103 MPa, which can meet the lubrication of manual transmissions and rear axles of diesel vehicles, various tractors and construction machinery. Medium and heavy duty gear oils are suitable for high-power construction machinery and large-tonnage trucks (such as domestic 42 t trucks, American-made 140 t mines, etc.).

At present, there are two incorrect ways to use the vehicle gear oil: one is not to change the oil; the other is to replace the gear oil with the used oil on the small tractor, causing serious wear of the gear.

Determine if the gear oil is available and determine the color of the gear oil. Gear oils with reddish and yellow colors are metamorphic gear oils, which should be replaced in time; check whether the gear oil maintains the slippery performance by hand grinding. If it is not possible, it needs to be replaced; if there is any strange smell, if necessary, replace the new oil. In order to prevent the gear oil from deteriorating and losing the lubricating effect, the gears and bearings are burned and damaged, resulting in mechanical accidents of the vehicle.

3 Tractor transmission, hydraulic dual-purpose oil

The transmission and hydraulic dual-purpose oil are mainly suitable for the mechanical equipment of the tractor or the engineering machinery transmission and the hydraulic suspension to jointly use one fuel tank. At present, China's Lanzhou Oil Refinery and Shanghai Refinery all produce this dual-purpose oil, and its quality is comparable to that of John Deere's products in the United States. The grades are 68 and 100 (enterprise standard). No. 68 is suitable for large, medium and small tractors, and No. 100 is suitable for imported tractors or high-power construction machinery. Transmission and hydraulic oil have the advantages of preventing friction, extending the life of the machine, reducing the number of oil changes, easy to start, anti-foam, anti-rust, etc. Since the cost of the tractor hydraulic transmission dual-purpose oil is relatively low, it occupies a certain position in China. Market share. However, many small and medium-sized tractors use oil instead of hydraulic oil to reduce hydraulic power, oil leakage, and shorten the life of hydraulic components. This type of transmission and hydraulic oil cannot be used in the brake system of the tractor. At present, Great Wall brand transmission-hydraulic-brake three-purpose oil has been widely used in China for tractors with a power of more than 180 horsepower. It meets the lubrication requirements of the "Dongfanghong" brand tractor transmission-hydraulic-brake system, and has obtained a drag on China. The approval of the technical department of the group ended the monopoly of imported lubricants for general-purpose lubricants, and was also recognized by the majority of manufacturers and rural users.

4 Grease

At present, there are three main types of grease used in China:

(1) calcium-based grease. The calcium base grease is obtained by thickening the lime. The advantages are: wide source of raw materials, low price, good lubricity, pumpability and water resistance. The disadvantage is that it is not resistant to high temperatures and has a low dropping point. The applicable temperature is 60 to 75 °C.

(2) Sodium lipid. The sodium base grease is obtained by thickening with a fire base, and the high temperature resistance is good, but the water resistance is poor.

(3) Lithium base grease. The lithium base grease is obtained by thickening with 12-hydroxystearic acid, and has the advantages of wide temperature range (-30 to 150 ° C), strong water resistance, mechanical stability, and good oxidation stability.

The use of lithium-based grease can reduce wear and reduce the number of oil changes. Currently, lithium-based grease has been widely used abroad.

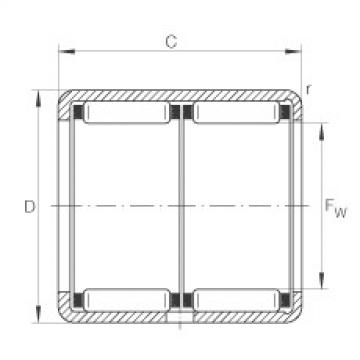

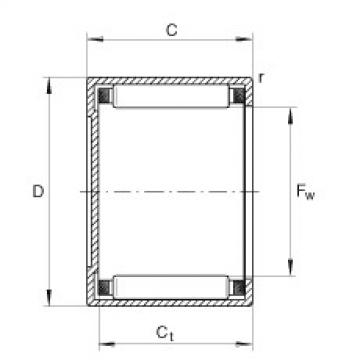

FAG Nadelhülsen - HK2030-ZW

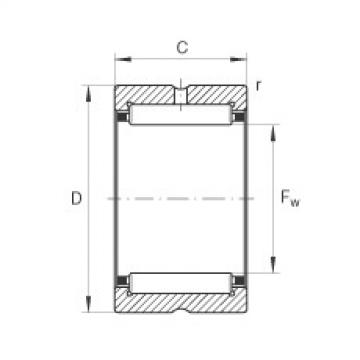

FAG Nadelhülsen - HK2030-ZW FAG Nadellager - RNA6902-XL

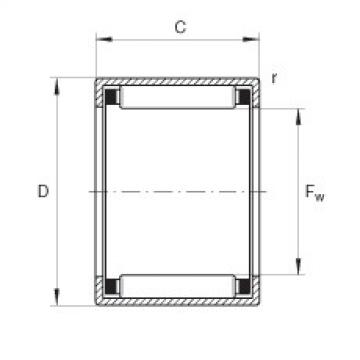

FAG Nadellager - RNA6902-XL FAG Nadelhülsen - HK2016

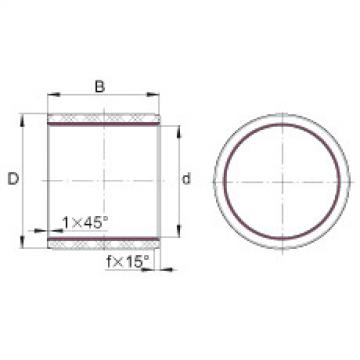

FAG Nadelhülsen - HK2016 FAG Gleitbuchsen - ZWB202415

FAG Gleitbuchsen - ZWB202415 FAG Nadelbüchsen - BK2016

FAG Nadelbüchsen - BK2016